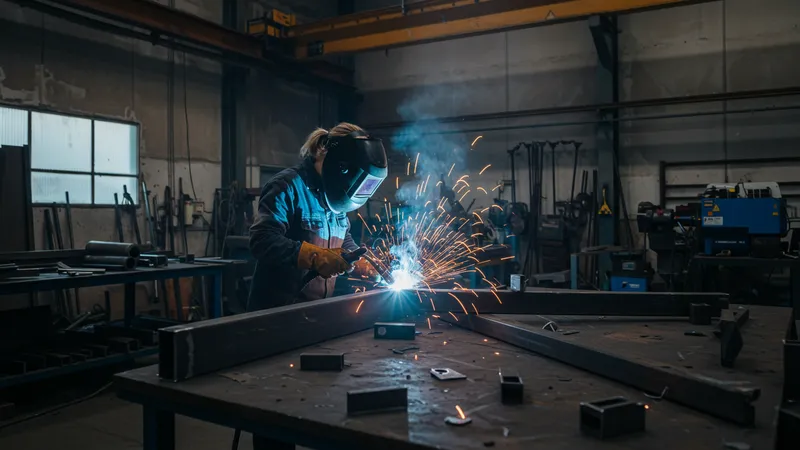

Welding Machines Explained: Types, Uses, And Buying Guide

Unveiling the Types: The Mig Welding Enigma

Mig welding, or Metal Inert Gas welding, is arguably one of the simplest techniques to master, yet it’s involved in the creation of massive steel structures. It uses a continuous feed wire and has a protective gas flow. Its ease of use makes it popular for beginners, yet versatile enough for pros. But there’s one more twist…

The true beauty of Mig welding lies in its adaptability across different materials, including stainless steel and aluminum. This flexibility has empowered DIYers and industrial manufacturers alike. What you read next might change how you see welding forever.

Many do not realize that Mig welding is not just limited to clean environments. Specialized setups allow for crucial fixes on-site in outdoor conditions. This adaptability makes it indispensable and contributes to its growing demand across various sectors. But wait until you hear about the secret behind its efficiency…

The coatings used in conjunction with Mig welders can significantly affect the quality of the weld, enhancing aesthetic appeal and durability. Next time you admire a gleaming metal fixture, remember that it likely owes its sheen to meticulous Mig welding. But that’s not even Mig welding’s standout feature…