Warehouse Management Systems: Boost Efficiency & Cut Costs

The Hidden Costs No One Talks About

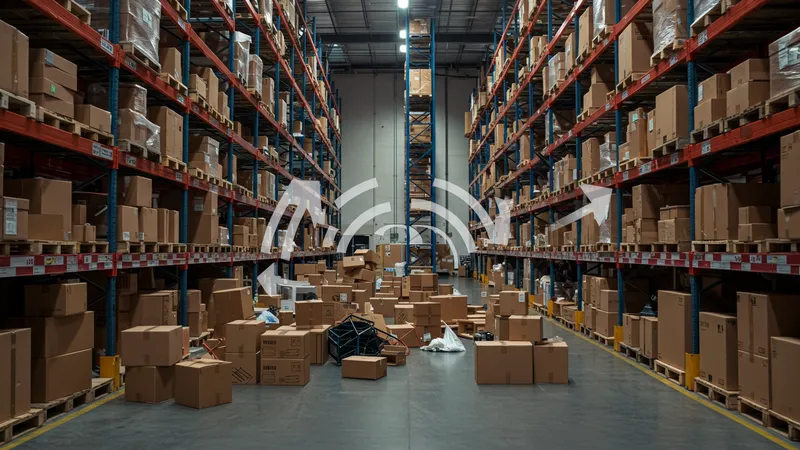

While the upfront cost of implementing a WMS might make some entities pause, the hidden costs of not having one are profound. For example, inventory mismanagement due to lack of a centralized system can lead to overstocking, which ties up capital and incurs storage costs. The impact of these inefficiencies can be staggering.

Warehouse mismanagement causes a ripple effect of issues, from delays causing damaged goods to dissatisfied customers and lost sales. Not addressing these hidden costs can consume profits in the long term, which brings us to a startling statistic: businesses report losing up to 20% in annual profits due to inventory inaccuracies. Have your eyes been opened yet?

Another aspect that’s less spoken about is the cost of integrating legacy systems with WMS. It can be a technical nightmare, filled with hidden fees and unexpected downtime. Yet, those who endure the transition often report a return on investment within two years. Isn’t that eye-opening? The transition not only streamlines logistics but also enhances integration across different departments.

On a more positive note, post-integration efficiency gains are incredible. More than just cost-cutting, it’s about unlocking potential. Businesses report improved accuracy and faster processing times. Lastly, keep this curveball in mind: every penny invested can boomerang into greater profits and greater molds of efficiency. But is that all there is? Think again.